We have all known the advantages of using blister packaging boxes before, and have also seen the wide range of applications of blister products. We have seen a variety of blister products, but we don’t know that many customers come to highlight the company’s image and product attributes. Customization is generally required for blister proofing. Only after the proofing is successful can subsequent production be carried out. Let’s analyze how to perform blister proofing below?

1. Determine the style: When customizing the product, the blister factory will design the blister style, and communicate and coordinate the designed blister product with the customizer. Confirm the design drawing of the blister product. After the customer confirms the design drawing, choose to develop the mold according to the complexity of the design drawing.

Blister packaging

2. blister proofing: After the customer determines the design drawing, according to the size required by the customer, manually lay the outline, use the prepared special plaster, pour the blank into the plaster, and form a plaster blank after weathering. The shape and accuracy of the gypsum blank can be deep processed by electric motor bed or manual polishing. At this point, the preliminary sample is ready, and polishing work is needed next. The polished parts are integrated and assembled into a complete plaster mold.

After the above 2 steps, we can see the proofing samples. According to the samples, we can produce suitable products. Generally speaking, it is a very simple process, but the operation is very complicated. Have enough experience.

Seven characteristics of transparent blister packaging

Transparent blister packaging has a display effect. Blister products are made of transparent plastic materials such as PVC and APET. There are many kinds of them. They are designed according to the shape and structure of different packaging items to ensure the perfect shape of the packaging items. At the same time, transparent blister Packaging can also control and master packaging costs.

1. Blister packaging products have strong supporting force and beautiful structure bottom. They are mostly suitable for electronic products, digital products, stationery pen holders, hardware accessories and other product holders. The structure of blister packaging products is specifically designed according to similar items. The specifications and dimensions of the materials used in the ground are only suitable for the goods around you. The packing is reasonable, and it is easier to grasp the packing list.

2. Blister transparent packaging box, super transparency, directly showing the beauty of the item, beautiful and generous appearance structure, good protection performance, can also design different styles of blister packaging products, control costs, generally suitable for cosmetic packaging, stationery Plastic packaging, sporting goods packaging, toy packaging, etc.

3. The transparent cover of the blister packaging has high transparency, the display items are transparent and visible, and the structure is beautiful. It is generally used for display and protection of the surface. A considerable part of the products are glued to the paper card after hot pressing, and it is not easy to fall off. Different styles of packaging have different styles of packaging. The company is equipped with professional designers to communicate directly, just for more beauty and more suitable.

4. Folded transparent blister packaging products, there are three folds and four folds. This type of product is usually used for the packaging of paper cards. Most of them are suitable for boutiques, gifts, small accessories, with hooks, which are convenient for sales display and packaging. The objects are easy to take out for viewing.

5. Double-folded transparent blister packaging products. This type of product is folded in half to form a box body, with buckles on the half-fold, strong protection and high transparency, directly showing the beauty of the item, and it is generally used for packaging items that are displayed in all directions, such as fishing gear. Packaging, ball packaging, home appliance packaging, digital product packaging, etc.

6. Three-fold three-dimensional transparent blister packaging, three-fold three-dimensional packaging, portable three-dimensional packaging can be set, strong three-dimensional effect, elegant display angle, suitable for packaging all-round display of all-round protection items, according to the items The structure and design ensure perfect shape and packaging.

7. High-frequency blister transparent packaging box, transparent packaging product, high transparency, the characteristic of this kind of product is that the packaging is not easy to fall off, the packaging box formed by heating and pressing the upper and lower blister products is strong, and the items are not easy to take out. Usually used Used in hardware accessories, stationery packaging, daily necessities, digital products and other packaging.

What is the reason for the bad blister box?

The reasons for the defective blister packaging box are nothing more than the following points, such as uneven thickness, pull lines, crystal dots, water lines or bubbles. Analysis of the causes of bad blister packaging boxes and management methods for how to solve them.

1. There are three main reasons for the uneven thickness of the blister packaging box.

①The problem of the shelf, that is, when you load the material on the machine, the adjustment of the position is very important. Once the company has some irregular or misplaced placement, it will cause the thickness of the blister box to be uneven. . Need to improve the position we should pay attention to when we put it on the shelf.

②The thickness of the sheet is not adjusted properly during the manufacturing process, which may cause uneven thickness. This requires a high-quality sheet supplier.

③The temperature changes are related. Different materials require different temperatures. Assuming that the ambient temperature is not adjusted to the appropriate temperature, it is easy to make the thickness of the blister packaging box uneven.

2. There are pull lines on the blister box. The reason for the pulling line is mainly related to the rationality and quality and safety of the industrial structure of the blister mold, and to a certain extent, it is also related to the operation of the blister machine and the selection of materials when putting it on the shelf. The solution is to find a high-quality blister mold manufacturer to establish a cooperation, and just notice a little bit when the materials are put on the shelf and the machine is adjusted.

3. There are crystal dots on the blister packaging box. On the one hand, materials with poor quality were selected, and on the other hand, impurities were mixed into the sheet. The solution requires a certain amount of sampling inspection, contacting the sheet supplier to replace the sheet.

Fourth, there are water ripples or bubbles on the blister box. The cause of water ripples has a lot to do with the molding speed of the blister box. The air bubbles are more likely to be caused by the poor quality of the sheet material and the infiltration of a large amount of air pollution during the production process. To solve this method, one is to pay attention to the internal control of the time of blister forming, and the second stage is to pay attention to the quality of the sheet.

Don’t throw away the disposable lunch box

When we pack some food outside, or when we order take-out online, we usually use transparent lunch boxes to store food. This plastic lunch box is disposable. If it is not handled properly, it will cause harm to the environment, so it is used up. Be sure to throw it in the trash can. Don’t throw it around. While enjoying the convenience of life, we will make a small contribution to protecting the environment. In addition to being thrown away, the lunch box can also be used for a second time to give you more value. Let me share one of the magical effects of the lunch box. The method is very simple. Every family can use it. Let’s take a look.

First, we take a disposable lunch box, the shape does not matter, it can be round or square, clean it. Then use an electric soldering iron to make some small holes on the lid, as small as possible, not too big. If you don’t have an electric soldering iron, you can use an awl to drill holes, or heat the iron wire to pierce your eyes.

After getting a good eye, it looks like this, so that’s it, let’s see how to use it.

We take out a white bottle and pour some into the lunch box, about half the lunch box is enough.

Then close the lid and put the lunch box in the refrigerator. White vinegar can effectively remove the peculiar smell in the refrigerator, and the small holes on the lid do not affect the volatilization of the white vinegar. At the same time, it effectively prevents the white vinegar from volatilizing too much and too fast, which can delay the volatilization speed of the white vinegar, which can keep the refrigerator for a long time. There is no peculiar smell, you can also give it a try.

Food packaging is exquisite

Food packaging is exquisite: one packaging box does not hold multiple dishes

Seeing that affordable Cantonese people love to pack after dinner parties, the Food and Drug Administration of Guangdong Province is here to send a reminder! Although everyone knows how to pack, there are still a lot of details inside.

What kind of dishes don’t you take home?

Vegetables bear the brunt. According to experts from the Food and Drug Administration, vegetables should not be packaged because they are rich in vitamins. Repeated heating will cause rapid loss of vitamins. In addition, repeated heating of vegetables will chemically react the nitrate in them to produce nitrite, which is harmful to the body.

What kind of dish should I eat quickly?

Seafood is rich in protein, and bacteria are especially preferred and should not be kept for a long time; starch-rich foods such as rice cakes are easily parasitized by staphylococci, and it is difficult to kill them even if heated at high temperatures. This kind of food is best eaten within 4 hours . All packaged foods should not be separated from each other, and it is best to eat them within 5-6 hours.

When is the food in the refrigerator?

In addition, there is a little trick after taking the food home, which is to wait for it to cool completely before putting it in the refrigerator. Because the heat brought by the food will cause the condensation of water vapor, the growth rate of mold will be accelerated, which will affect the food storage in the entire refrigerator.

The reporter saw a lot of neighbourhood pictures to save trouble or to save packing boxes, and the rest of the dishes were packed together and taken away. Experts suggest that it is best not to do this. Packed food should be stored separately, and packed food should be separated into clean, airtight containers immediately after returning home. Because the growth rate of microorganisms in different foods is different, storing them separately can effectively inhibit the growth rate of microorganisms while avoiding cross-contamination.

How hot is packed food?

Finally, remember to pack the food back into the pot and reheat it. The food stored in the refrigerator must be returned to the pot for heating after being taken out. The temperature of the refrigerator can only inhibit the growth of bacteria, and cannot completely kill them. If the packaged food is not heated completely before eating, it is easy to have gastrointestinal diseases.

It is worth noting that the temperature of heating food should reach at least 70℃; the heating time of packaged seafood should be controlled at 4 to 5 minutes. Before returning to the pan and heating, you can judge whether the food has deteriorated through your senses. If it feels abnormal, don’t eat it again.

Nine kinds of food packaging boxes, each of which will absolutely amaze you

Nine kinds of food packaging boxes, each of which will absolutely amaze you. It is simply a masterpiece

The nine photos recommended by the editor today are actually the packaging of nine kinds of food. Food packaging boxes are generally very simple, but today’s each is very magical, let us know that the original packaging box can also have so many uses

First picture

The picture in the picture is spaghetti, you can know how much you have eaten every time you eat

Second picture

The picture is a tea bag that will bloom, it looks very nice

Third picture

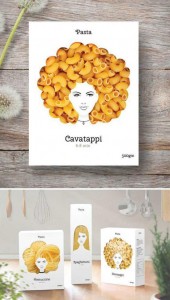

The picture shows the packaging of spaghetti. Each shape of the pasta is made into the hairstyle of the girl’s hair, which is very recognizable.

Fourth picture

The picture shows a very reasonable pizza packaging, which will help you sort the pizza in advance, and will not touch the pizza when you grab it with your hands.

Fifth picture

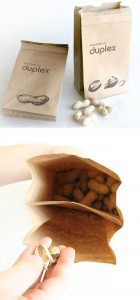

In the peanut packaging bag in the picture, one side is used to put peanuts, and the other side is specially used to put peanut shells.

Sixth

The picture shows a box of fresh milk, the box will gradually change color as the milk shelf life decreases, until the milk deteriorates, and the entire milk box turns orange

Seventh

The picture is a shockproof egg box, so you don’t have to worry that the eggs in the box will break due to vibration.

Eighth

The picture is the packaging box of potato chips, and this bucket can also be turned into a bowl for potato chips

Ninth picture

The box in the picture is used to hold honey, and this box is made of beeswax. Finally, the beeswax box can be used as a candle.

After reading the packaging boxes of these nine kinds of food, do you feel admiration for the ideas of these designers?

Plastic bags, packing boxes, hot food can cause cancer

Plastic can be said to be ubiquitous in life, and in addition to environmental issues, the most worrying thing is food safety:

In the morning, I bought a bun and fried dough sticks, and packed them in plastic bags when they were hot from the oven; when they were packed and ordered, all kinds of food were directly packed into plastic boxes; even some convenience stores directly packed the bento in plastic boxes. Put it in the microwave to heat up…

At this time, some people couldn’t help but wonder: whether heating plastic products or filling them with hot food will release toxic substances and even cause cancer? Let’s explore the truth together~

1. Not all packing bags and packing boxes can hold food

Food grade plastic bags that meet the national standard can hold hot food

Common plastic bags on the market are generally made of polyethylene (PE), but only food-grade plastic bags that meet the national standard can hold hot food.

However, even food-grade plastic bags must not be heated in a microwave oven or steamed in a pot. When heated, the temperature is very high, exceeding the melting point of the plastic bag, the plastic will be deformed, melted, and even stick to the food.

Moreover, experts remind that although food-grade plastic bags are non-toxic, the printing ink on the surface of the plastic bags is not completely non-toxic. If the temperature is too high, there may be a certain food safety risk.

[Guidelines for the safe use of plastic bags]

① Use plastic bags printed with special words such as “food grade” or cutlery logos to store food;

②Before bagging, the food temperature should not exceed 100℃;

③Do not retort plastic bags or packaging bags for a long time;

④ Heating oil-rich foods without wrapping in plastic bags.

2. Only the products with “pp5″ at the bottom are qualified products

In the program of the great doctor, there was an experiment in which hot oil of about 150°C was put into lunch boxes of different plastic products. It was found that some lunch boxes did not change significantly, some were deformed, and some were deformed. The bottom of the box even melted directly!

Experts remind: There are three standards for plastic lunch boxes, 1, 5, and 6. Relatively speaking, 1, 6 is not resistant to high temperatures, and 5 can withstand high temperatures of about 200 ℃, and can be heated in a microwave oven.

Therefore, when using plastic lunch boxes, pay attention to choosing qualified products marked “PP5″ at the bottom.

It should also be noted that some packaging boxes, even if the box body is “5”, but the lid may not be, so the lid should be removed when heating. Especially if the microwave oven is heated too tightly, it may burst.

Since there are so many points to pay attention to in packing bags and packing boxes, what about beverage bottles, the drinks are poured into them, but they have to be stored for a long time. Some people even like to reuse them. Will there be certain health threats?

3. Can the beverage bottle be kept for reuse?

Nowadays, many beverage bottles are good-looking and sturdy. It is a pity to throw them away. Many people will wash them after drinking, and then leave them to fill with water or some beans, whole grains, or even pickles. But are these methods suitable?

In fact, the judgment method is very simple. Look upside down~ When the plastic bottle is upside down, there will be triangles and numbers at the bottom.

Mark “1” at the bottom, throw it away after drinking

Plastic bottles containing mineral water, juice, and carbonated beverages usually have “1” written on the bottom.

No. 1 plastic, also known as polyethylene terephthalate (PET). This material has poor heat resistance, the maximum use temperature does not exceed 70 ℃, it is easy to deform when heated or filled with boiling water, and it will also dissolve harmful substances.

Some studies have also found that after 10 months of use, “1” plastic products will release carcinogen DEHP, and the more repeated use, the higher the probability of releasing carcinogens and the more bacteria that will breed.

Therefore, this kind of plastic bottle not only can’t hold hot water, but also don’t reuse it. It’s best to throw it away after drinking it.

Plastic bottle pickles are more convenient? Generally not recommended

Generally speaking, plastic bottles and metal utensils have poor acid resistance. It is recommended to use special glass and ceramic products to pickle them.

If pickling vegetables in plastic bottles, choose PET products as much as possible and keep them away from high temperatures. In addition, avoid plastic barrels made of polyethylene, which can react with ingredients such as sodium chloride in pickles and produce harmful substances.

The water cup is also plastic, why can it be used? The key point is…

Speaking of this, many people will wonder again, many of the daily drinking cups are made of plastic, can they not be used anymore?

The bottom of some plastic cups is marked with “5”. As we said above, this material has strong heat resistance and can be filled with hot water; some plastic cups have a bottom with “7”, which is not suitable for hot water.

Like some space cups, the bottom of the cup is usually “7”, which is polycarbonate (PC). This material is very transparent and hard, has a smooth hand feel, is strong and resistant to falling, but is not suitable for holding water that is too hot.

This material may release bisphenol A at high temperatures, and bisphenol A is an endocrine disruptor that can cause endocrine disorders, and the higher the temperature, the more release.

The paper lunch box is slippery to the touch

Was it waxed?

Now paper packaging boxes are also very popular, such as pizza, burgers and other foods are used. So what is the slippery layer on it? Can it be heated in a microwave oven?

This slippery layer is a layer of plastic film called “polyethylene coating”. During casting, a thin polyethylene plastic coating is plated on the paper surface, which is equivalent to a plastic film covering the paper surface.

In this way, the paper lunch box can not only withstand the high temperature of about 90 ℃, but also can well isolate the water, pack food, and deal with cold and hot drinks, all without any problem.

However, under the high temperature of the microwave oven, the plastic film may decompose toxic substances, so try not to use wrapping paper to heat food.

Paper straws are soft and loose

Can it still be used?

It is not difficult to find that almost all milk tea shops and coffee shops have replaced paper straws. However, the paper straws that are “first out of the world” are frequently complained:

Every time you poke the lid of the cup, you have to use a lot of effort; I finally poke the paper straw in. The straw is soft before drinking a few sips of the milk tea. Is it really safe to drink a mouthful of paper?

The main risk of paper straws lies in the fact that during use, there may be harmful substances such as glue and additives in the paper straws that decompose into the beverage, especially at high temperatures.

However, under normal circumstances, paper straws that meet the national food safety standards are relatively safe and can be used with confidence.

If the source of the paper straw is not clear, it is best to do the following:

① Shorten the contact time between the paper straw and the drink as much as possible, and try to drink it within 1 hour;

②The straws currently on the market can generally withstand a temperature of 45°C, so do not insert the straws into overheated drinks;

③In the use process, avoid bad habits, such as biting the straw, so as not to produce debris or debris to contaminate the food.

How to correctly choose transparent plastic packaging boxes

There are always many problems in life that make us unable to choose, but we will always find a solution by constantly summing up experience, such as how to choose a plastic packaging box?

1. Isolation performance: According to different requirements for product packaging, plastic packaging materials should have a certain barrier effect on moisture, water vapor, gas, light, odor, heat, etc.

2. Better economic performance: Plastic packaging materials should have a wide range of sources, convenient materials, and low cost. After use, plastic packaging materials and packaging containers should be easy to handle and not pollute the environment.

3. Good safety performance: the toxicity of the plastic packaging material itself should be low, so as not to contaminate the product or affect human health; the packaging material should be non-corrosive and have the effect of preventing insects, moths and inhibiting microorganisms.

4. The use of plastic packaging materials is related to the cost and safety performance of product transportation.

5. Appropriate processing performance: plastic packaging materials should be easy to process, easy to make various packaging containers, easy to mechanize and automate packaging operations.

Tips for storing food plastic packaging

There are many diligent and thrifty housekeepers who like to save up used plastic packaging, cartons and cartons. Although this is a frugal and low-carbon behavior, Beijing Plastics Factory would like to remind everyone that these wastes should also be disposed of in time, otherwise It may have bad consequences.

Research has shown that used plastic packaging, especially plastic packaging bags containing fresh food, will leave a large number of deadly bacteria such as streptococcus, E. coli, etc., and cartons and cartons are gathering places for dust and mold.

Therefore, we suggest that you should not use plastic packaging bags that have been used for vegetables and raw meat to hold food anymore. It is better to clean up such waste products such as plastic packaging bags and cartons at home on a regular basis, otherwise it may attract various trends. Reptiles such as insects, cockroaches, and ants breed germs.

What are the advantages of flocking materials for blister packaging

Flocking packaging for blister packaging material refers to coating a layer of glue and a layer of chemical fiber on the original packaging material to protect the product and improve the product level. Its primary application areas include: cosmetics occupations, IT electronic digital occupations, hardware tools occupations, advanced gift packaging industry, etc. The substrate used is generally PS or PVC. What is the flocking material of blister packaging? What are the advantages?

Flocking packaging material refers to coating a layer of glue and a layer of chemical fiber on the original packaging material to protect the product and improve the product level. Its primary application areas include: cosmetics occupations, IT electronic digital occupations, hardware tools occupations, advanced gift packaging industry, etc. The substrate used is generally PS or PVC. Flocking blister is a blister tray made of special materials. Paste a layer of velvet-like material on the surface of general plastic hardware to make the surface of the tray have a velvet-like feel and improve the level of packaging. botany.

velvet suction characteristics: strong three-dimensional effect, bright color, soft hand feeling, luxurious and noble, rich and warm, vivid and tasteless, non-toxic and tasteless, heat preservation and moisture-proof, no hair loss, wear resistance, seamless lubrication.

The advantages of flocking packaging.

Flocking blister packaging is a blister product that is rarely used and produced. In the product packaging industry, since there are not many products packaged in hairless bubbles, they are generally used as substrates.

Flocking blister packaging is a kind of high-end product packaging with beautiful appearance. It is usually used for some high-end product packaging, such as chocolate, cosmetics, gifts, jewelry, spectacle cases, watch boxes, wine, etc. The most important of these plastic products The material is PS material, and then flocking is to glue a thin layer of rubber cotton on the surface of the material to form a flocked plastic product.

Flocking plastic products have beautiful appearance, soft hand feeling, and various colors, which can be selected according to the product image. At the same time, it is necessary to make the product more attractive, so that customers are more likely to have a good impression and desire to buy the product. Flocking plastic packaging products must have the outstanding advantages of common packaging.