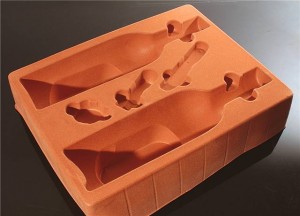

Most people use some sort of plastic packaging every day. From thermoformed packaging to retail packaging to utility box plastics, plastic containers are simply part of everyday life. Packaging designers have worked over the years to give society easy to use, convenient plastic and clamshell packaging solutions. But how has plastic changed over time? This article is going to provide a brief overview of the evolution of plastic containers to help you understand how your favorite plastic containers came to be what they are today.

Between the years 1862 and 1869, there were two man-made plastic inventions. In 1862, Alexander Parkes revealed a material, called Parkensine, derived from cellulose that could be heated and molded into any shape. And in 1869, John Wesley Hyatt invented a synthetic polymer. Hyatt aimed to create a substitute for ivory and eventually found that if he treated cellulose, derived from cotton fiber, with camphor, he could create a plastic that could be formed into various shapes. For one of the first times in history, manufacturing was not limited to what nature could supply.

Saran, which we know today as saran wrap, was accidentally discovered in 1933 by Ralph Wiley. Wiley, a Dow Chemical lab employee, discovered that the plastic, polyvinylidene chloride, could cling to almost any material. While it was originally used to protect military equipment, it eventually was used to maintain food freshness.

Other infamous plastic inventions include the first major commercial plastic spray bottle, developed in 1946 by Dr. Jules Montenier, plastic garbage bags, invented by Harry Wasylyk and Larry Hansen in 1950, and zipper storage bags, invented by Robert W. Vergobbi in 1654.

It was in the 1960s when people became aware of the possible environmental drawbacks from plastic materials. In the 1970s and 1980s, concerns about plastic waste increased further. However, it was the plastic industry that actually created recycling as a solution. The plastic industry began to lead drives to collect and reprocess recyclable materials and those efforts have continued today. These efforts are crucial, especially seeing as how mass amounts of plastic ends up in the ocean, where it causes at least $13 billion in damages each year.

While the reputation of plastic has suffered for many years, the plastic industry is continuing to make positive changes. Whether it’s offering reusable clamshell packaging solutions or furthering recycling programs, today’s plastic is becoming more and more environmentally-friendly.

Now that you know a bit more about how plastic came to be what it is today, you can do your part to contribute to eco-friendly plastic options. When it comes to containers or clamshell packaging solutions, always choose reusable options and always remember to recycle.

FROM:Click It Clam